Normal Wear

In order to identify compromise of a lock it is important to know what the lock components and keys look like when they are used normally.

The amount and nature of the wear on components varies and is highly dependent on the lock, key, and component materials. The most common material for pin-tumbler locking cylinders, keys, and components is brass. Cylinders and components (pins, levers, wafers, etc) also commonly use nickel-silver, steel, and other materials. Keys are made from a wide variety of materials besides brass, such as nickel-silver, aluminum, iron, steel, zamak, and various proprietary alloys.

The nature of wear also depends on the design of the key and the components. Unfortunately, I cannot display all possible combinations of designs and materials. Regardless, it is the duty of the forensic locksmith to conduct laboratory tests if an unknown combination is found during an investigation.

The following is a microscopic examination of different stages of wear on a standard pin-tumbler cylinder (Falcon FA3, 6 chambers, pinned for 5) that is made of brass. Bottom pins in this cylinder have rounded tips. Prior to disassembly, the key to this cylinder was used no more than ten times. For the sake of space, I will only show 1-2 pins of each stage, rather than all 5.

5,000 Uses | |

|---|---|

|

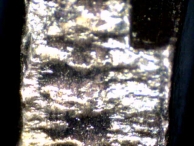

At 5,000 uses (roughly 5-6 years of use) the front pin has no milling marks, and almost all scratches have been polished away. From this point on wear looks similar to this, with light markings sometimes being created by wear of the key. |

|

Compared to other pins, pin 5 (the farthest back) continues to show reduced signs of wear and retain its milling marks. We can also now see that wear is not evenly distributed on this pin, as it resembles an oval shape. Compare with above picture and 1,500 use pictures. |

|

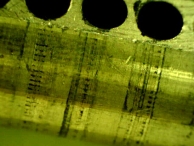

They key continues to wear down, with small craters from the previous example now very large and uneven. Slight imperfections like this in the key will cause light, seemingly random scratching on the soft brass on the pins. Stronger key materials may even act as a file against pins. |

|

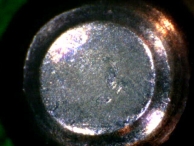

At 5,000 uses the plug continues to show increased wear, though not much has changed. More pronounced staggering of wear and lubricant can be seen along the circumfrence of the plug. Compare with example at 1,500 uses. |

|

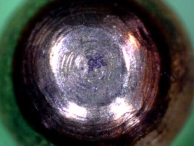

The face of a lock that has seen moderate to heavy use will have many dents and imperfections caused by normal use. How many times have you went to unlock a door and slightly missed the keyway? In the photo, many small dents and scratches from normal use are visible. |

|

In shoulder stopped locks (almost all modern locks qualify), continued use will cause light impact marks along the face of the plug. This is normal, and should not be confused with the extreme material displacement that occurs during key bumping. |

Other Factors

In cylinder based locks, the use of different materials for the plug and cylinder reduces wear. This also applies to wear on the pins, but most changes to pin material are to increase resistance to destructive entry, not longevity.

The speed at which a key was cut will translate into smooth or jagged ramps on the key. In some cases, a sufficiently strong key material, such as steel, with jagged ramps acts as a file on the pins, causing wear at an accelerated rate. See the key analysis page for more information.